That perfect spot for your wall-mounted TV or new reading lamp rarely lines up with an existing outlet. Before you reach for a clumsy extension cord, you might consider a more permanent fix. The process of extending electrical wiring allows you to move power exactly where you need it, creating a cleaner and safer setup. While the idea can seem complex, it’s based on a few core principles: shutting off the power, using the right materials, and making every connection inside a protective junction box. This article will demystify the task, providing clear, actionable steps for a successful project and helping you recognize when the job requires a professional’s touch.

Key Takeaways

- Master the Safety Basics: Before starting any electrical work, your first step is always to turn off the power at the breaker. Your second is to confirm the circuit is dead with a non-contact voltage tester—this simple check is non-negotiable for your safety.

- Build a Safe and Lasting Connection: Every wire splice must be housed inside an accessible junction box to prevent fire hazards. It’s also critical to match the gauge of your new wire to the existing wire to ensure it can safely handle the electrical load.

- Know When to Call for Help: While moving an outlet can be a manageable project, tasks involving new circuits, high-voltage systems like generators, or anything that makes you feel uncertain are best left to a professional electrician to guarantee safety and code compliance.

What Does It Mean to Extend Electrical Wiring?

Ever found yourself wishing an outlet was just a few feet to the left? Or maybe you’re installing a new light fixture, and the existing wire is just shy of reaching? That’s where extending electrical wiring comes in. At its core, it means safely adding length to an existing wire to move or install an electrical component. This isn’t as simple as taping two wires together; it involves a process called splicing.

To do this correctly, you must connect the old wire to a new piece inside an accessible junction box. This small enclosure protects the connection point and is a non-negotiable part of meeting electrical codes. The splice itself is made using approved connectors that ensure a secure and lasting bond. Hiding a splice inside a wall without a junction box is a serious fire hazard and against code. The goal is to create an extension that is just as safe and reliable as a continuous, unbroken wire, ensuring your home’s electrical system remains secure.

Common Reasons to Extend a Wire

You might need to extend wiring for several common home improvement projects. The most frequent reason is relocating an outlet or a light switch during a remodel. If you’re moving a wall-mounted TV, shifting your home office setup, or rearranging your kitchen, you’ll likely find the existing outlets aren’t in the right spot. Another popular reason is adding new fixtures, like under-cabinet lighting or a ceiling fan, where the original wiring doesn’t quite reach. Sometimes, old wiring is simply too short to work with after being damaged near the electrical box, requiring a small extension to make a safe connection for a new device.

The Basic Parts You’ll Be Working With

To extend a wire safely, you’ll need a few specific parts. The most critical component is a junction box, which is an enclosure that houses and protects the wire splices. You must use junction boxes wherever you join wires together; it’s a fundamental rule of electrical safety. You’ll also need electrical wire of the same gauge (thickness) as the existing wire. To connect the wires, you’ll use connectors like wire nuts or Wago-style lever nuts. These create a secure mechanical and electrical bond. Finally, you may need electrical tape for extra security and a cover plate for the junction box to keep it sealed. Having the right materials is the first step in any successful electrical repair.

Safety First: Your Pre-Work Checklist

Before you touch a single tool, it’s crucial to run through a safety checklist. I know it’s tempting to jump right into a project, but when it comes to electrical work, a few minutes of prep can prevent serious injury and costly mistakes. These aren’t just suggestions; they’re the essential, non-negotiable steps every person should take before starting a wiring project. Think of this as your pre-flight check. By methodically shutting down the power, gearing up properly, and double-checking your work area, you create a safe environment that lets you focus on getting the job done right.

Shut Down Power at the Breaker

This is your first and most important step. Always turn off the electricity to the circuit you plan to work on. Head to your home’s main electrical panel—often found in the basement, garage, or a utility closet—and locate the breaker for the correct room or area. Flip it firmly to the “OFF” position. If you have any doubt about which breaker controls the circuit, the safest move is to shut off the main breaker, which cuts power to the entire house. This is a fundamental rule for all electrician repairs, whether you’re a pro or a DIYer.

Gear Up: Your Essential Safety Equipment

Having the right gear is about more than just convenience; it’s about protection. At a minimum, you’ll need safety glasses to shield your eyes and a pair of insulated gloves. It’s also a good idea to wear closed-toe shoes with rubber soles. Beyond personal protective equipment, make sure you have all your project materials organized and within reach. This includes having the correct wire, wire nuts, electrical tape, and a properly sized junction box ready to go. Being prepared is a key part of any safe residential electric project and helps you avoid taking risky shortcuts later on.

Double-Check for Live Wires with a Voltage Tester

So, you’ve flipped the breaker. But are you positive the power is off? This is where you “trust but verify.” Use a non-contact voltage tester to confirm that the wires are dead before you touch them. Simply bring the tip of the tester close to each wire you intend to work with. If the tester lights up or beeps, there is still an electrical current present. You’ll need to head back to the breaker panel and figure out why. This simple, inexpensive tool provides the final confirmation that your work area is safe and is a step that professionals never, ever skip.

The Right Tools and Materials for the Job

Walking into a hardware store’s electrical aisle can feel overwhelming, but having the right tools and materials is the most important step toward a safe and successful project. Before you make a single cut or connection, you need to gather your gear. This isn’t just about convenience; it’s about safety. Using the wrong wire gauge or an improper connector can create a serious fire hazard. Think of it as setting up your kitchen before you start cooking—you wouldn’t try to chop vegetables without a cutting board and a sharp knife.

The same principle applies here. Whether you’re adding an outlet for a new TV or preparing a circuit for a major upgrade, the quality of your materials directly impacts the safety and reliability of your home’s electrical system. This is especially true for larger projects, like preparing your home for a standby generator installation, where every connection needs to be perfect to handle the load during an outage. Taking the time to get the right supplies ensures your work will be secure, compliant with electrical codes, and built to last. Let’s break down exactly what you’ll need to get the job done right.

Your Must-Have Tool List

Having all your tools and materials ready before you start saves you from making extra trips to the store and helps you stay focused. Here’s a basic checklist of what you’ll need for most wire extension projects. For tools, grab a pair of wire strippers, needle-nose pliers, a utility knife, and a set of screwdrivers.

On the materials side, you’ll need electrical wire of the correct gauge for your circuit, a junction box to safely house the connections, and the right connectors, like wire nuts. Don’t forget a roll of electrical tape for securing connections and outlet or switch covers to finish the job cleanly. Having these items on hand ensures you can complete your work safely and efficiently without cutting corners.

Connectors Explained: Wire Nuts vs. Wago vs. Splice Kits

When you join wires together, the connection needs to be rock-solid. The most common way to do this is with wire nuts—those little plastic caps you twist over the ends of the wires. They’re reliable and have been used for decades. However, you might also see push-in connectors, like those made by Wago. These are often easier for beginners to use because you simply push the stripped wire into a port, and a spring-loaded clamp holds it tight.

For underground or outdoor wiring, you might need a special splice kit that provides a waterproof seal. Each type works well, but it’s important to choose the right one for your specific project to ensure a secure and lasting connection. If you’re unsure, our team handles all types of electrician repairs and can advise on the best materials.

How to Choose the Correct Wire Gauge and Junction Box

Selecting the right wire gauge is critical for safety. The “gauge” refers to the thickness of the wire, and a lower number means a thicker wire that can handle more electrical current. Using a wire that’s too thin for the circuit’s amperage can cause it to overheat and create a fire risk. For most standard home circuits, a 12-gauge wire is appropriate for a 20-amp circuit, while a 14-gauge wire is used for 15-amp circuits.

You also need to choose the right size junction box. The box must be large enough to safely contain all the wires and devices without overcrowding. As a rule of thumb, always leave at least three inches of wire extending from the box to make connections easier and safer to work with.

4 Proven Methods for Extending Electrical Wires

Once you’ve handled the prep work, you can get to the main event. Extending electrical wiring isn’t a one-size-fits-all task; the best approach depends on your project. Whether you’re moving an outlet a few inches or running a line to a new location, one of these four methods will get the job done safely. We’ll walk through each one, from a simple fix for short wires to running a brand-new line.

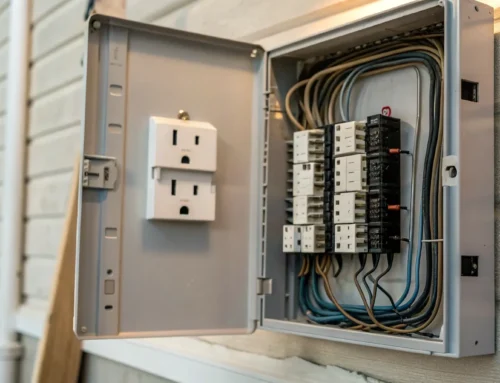

Using a Junction Box

A junction box is a protective case for wire connections. It’s the safest way to extend a wire, and the National Electrical Code (NEC) requires all splices be contained within one. This prevents accidental contact and contains potential sparks. The most important rule is that a junction box must always be accessible—never buried behind drywall. It needs a cover plate so you or an electrician can inspect the wiring later.

Mastering Wire Splicing

Splicing is simply joining two wires. To do it right, use wire nuts. After stripping about a half-inch of insulation, hold the bare wire ends together and twist them clockwise. Then, screw on a wire nut until it’s snug. Always connect same-colored wires: black to black (hot), white to white (neutral), and the ground wires (green or bare copper). Remember, every splice must live inside a junction box. If you’re ever unsure, it’s best to have a professional electrician take a look.

Creating Pigtails for Short Wires

Ever open an outlet box to find the wires are too short to work with? The solution is a pigtail—a short piece of wire (about 6 inches) that you add to the existing wire. This gives you the length needed to comfortably connect to a switch or outlet. You’ll connect one end of the pigtail to the short wire with a wire nut and the other end to the device. This simple trick saves you from replacing the entire wire and makes working in a crowded box much easier.

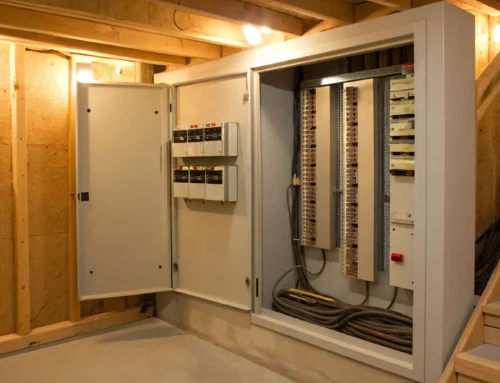

Running a New Wire

Sometimes, the best solution is to run a completely new wire. This is common when moving an outlet, adding a fixture, or supplying power for a major appliance. It’s also a necessary step when installing a home generator, which requires its own dedicated circuit. While more labor-intensive, running a new wire eliminates mid-run junction boxes for a cleaner installation. If you’re replacing an old wire, ensure it’s completely disconnected from power before abandoning it.

How to Splice and Connect Wires Correctly

Splicing, or joining wires together, is the fundamental skill you need to extend an electrical circuit. Whether you’re adding a new outlet or need a bit more length to install a light fixture, a proper splice ensures a safe and reliable flow of electricity. Doing this correctly isn’t just about making things work; it’s about preventing serious hazards like electrical fires. The process involves carefully stripping the wires, making a secure physical connection, and protecting that connection inside a junction box. It’s a methodical process, but one that is absolutely crucial to get right.

A Step-by-Step Guide to Making a Secure Connection

Creating a solid connection is the heart of any wiring job. Start by carefully stripping about five inches of the outer plastic sheathing from the ends of the cables you’re joining. Next, use a wire stripper to remove about half an inch of the colored insulation from the individual wires, exposing the copper beneath. Now, match the wires by color—black to black (hot), white to white (neutral)—and twist the exposed copper ends together clockwise. Do the same for the bare copper or green ground wires. To finish, screw a wire nut over each twisted pair until it’s tight. Give each wire a gentle tug to confirm it’s secure inside the nut.

How to Properly Secure Wires in a Junction Box

Every wire splice must be contained within a junction box—this is a non-negotiable rule required by electrical code. A junction box protects the vulnerable connections from damage, moisture, and dust, and contains any potential sparks to prevent a fire. Once your wires are spliced, carefully fold them into the box, making sure not to overcrowd it or bend the wires too sharply. Secure the junction box to a stud or joist so it’s stable, and always attach the cover plate. Most importantly, the box must remain accessible, meaning you can’t bury it behind drywall or insulation. You always need to be able to get to it for future electrician repairs.

Grounding and Managing Your Wires

Proper grounding and wire management are essential for a safe electrical system. The ground wire provides a safe path for electricity to escape in case of a short circuit, preventing dangerous shocks. Always connect all ground wires (usually bare copper or green) from every cable inside the junction box. It’s also critical to use the same gauge, or thickness, for the new wire as the existing wire to ensure it can handle the electrical load. When you place the wires in the box, make sure at least three inches of wire extend out from the opening. This gives you enough slack to work safely now and for any future residential electric projects.

Understanding Local Electrical Codes

Navigating electrical codes can feel like learning a new language, but it’s all about one thing: safety. These rules aren’t just suggestions; they are standards designed to protect you, your family, and your home from electrical hazards. While codes can vary by location, they are all based on the National Electrical Code (NEC), which sets the benchmark for safe electrical design and installation across the country. Getting familiar with the basics is a crucial step before you even think about touching a wire. It ensures your project is not only successful but also secure and up to standard.

Key National Electrical Code (NEC) Guidelines

One of the most important rules in the NEC is that every electrical connection or splice must happen inside a covered junction box. This is a non-negotiable. The box protects the vulnerable connection points from damage, dust, and moisture, which helps prevent short circuits and fires. Just as importantly, the code requires that this junction box must always be accessible. This means you can’t bury it behind drywall or seal it up in a wall. You need to be able to get to it for future inspections or repairs without having to tear things apart.

Rules for Junction Box Placement and Accessibility

So, where do you put the junction box? The rule is simple: wherever you splice wires together. These boxes are the designated safe zones for your connections. When you place a junction box, make sure it’s securely mounted to a stud or another firm surface. The cover plate needs to remain exposed and accessible, which usually means it will be flush with the drywall. Hiding a junction box creates a serious fire hazard and makes future electrical work a nightmare. Always plan your wire extension so the junction box can be placed in an attic, basement, or closet.

Requirements for Wire Protection and Length

The NEC also has specific rules about how much wire you need inside the junction box. When a wire enters the box, at least six inches of it must extend from where it comes out of its outer protective sheathing. On top of that, at least three inches of that wire must extend past the front edge of the box. This might seem overly specific, but there’s a good reason for it. This extra length gives you enough slack to safely and easily make connections with wire nuts or other connectors without having to pull or strain the wires.

When You Need to Pull a Permit

Anytime you’re adding a new circuit or making significant changes to your home’s wiring, you’ll likely need to pull a permit from your local building department. This process ensures a qualified inspector reviews the work to confirm it’s done safely and to code. If you’re just replacing a light fixture, you probably don’t need one, but extending a circuit often falls into a gray area. When in doubt, it’s always best to call a professional. A licensed electrician will know exactly when a permit is required and can handle the entire process for you, ensuring everything is safe and compliant for any electrical repairs or larger projects.

Common Wire Extension Mistakes to Avoid

Even a seemingly straightforward project like extending a wire can go wrong if you’re not careful. Knowing the common pitfalls ahead of time is the best way to ensure your work is safe, effective, and up to code. From using the wrong materials to making a simple connection error, small mistakes can lead to big problems, including electrical shorts, fire hazards, or failed inspections. Let’s walk through some of the most frequent missteps so you can confidently avoid them in your own project. Taking a moment to double-check your work against these common errors will give you peace of mind and a much safer result.

Using the Wrong Wire Gauge or Materials

One of the most critical mistakes is using a wire with the wrong gauge. The gauge indicates the wire’s thickness, which determines how much electrical current it can safely carry. Using a wire that’s too thin for the circuit’s amperage can cause it to overheat, melt its insulation, and create a serious fire risk. Always match the new wire’s gauge to the existing wire in the circuit. You can find the gauge printed on the wire’s outer sheathing. Similarly, make sure you’re using the correct type of wire for the location—for example, standard NM-B cable is for dry, indoor locations only.

Making Weak or Unsafe Connections

A secure connection is a safe connection. The biggest culprits here are loose wire nuts or connectors. If a wire isn’t held tightly, it can create tiny electrical arcs that generate intense heat, eventually melting the connectors and wires and potentially starting a fire. When you twist on a wire nut, make sure you’re catching all the wires and twist until it’s snug. Give each wire a gentle tug afterward to confirm it’s secure. If you find yourself dealing with flickering lights or outlets that have stopped working, it could be due to a poor connection that needs professional electrician repairs.

Overlooking Critical Safety and Code Rules

Electrical codes aren’t just suggestions; they’re safety standards designed to protect you and your home. A major rule that often gets missed is that every wire splice must be contained within an approved junction box. Furthermore, that box must always remain accessible—never bury it behind drywall or plaster. Another common code violation is cutting wires too short. The National Electrical Code (NEC) requires at least six inches of free wire extending from the box opening to make connections safer and easier to work on. If you’re ever unsure about these rules, it’s always best to consult a professional for your residential electric needs.

Know Your Limits: When to Call a Professional Electrician

I love a good DIY project, but I’ve learned that some jobs are best left to the pros. Electrical work often falls into that category. While extending a wire can seem straightforward, one wrong move can lead to serious risks like shocks or fires. Knowing when to put down the tools and pick up the phone is a sign of a smart homeowner. If your project involves complex rewiring, high-voltage equipment like a generator, or if you’re just feeling unsure, calling a professional is always the right move for your safety and peace of mind.

For Complex or Large-Scale Projects

What starts as moving an outlet can quickly become a bigger job, especially in older homes. If your project involves adding a new circuit, rewiring a room, or if you find a confusing web of wires, it’s time to pause. As one homeowner put it, “If you’re not sure exactly what you’re doing, it’s worth paying a professional.” A licensed pro has seen it all and can safely handle unexpected challenges, ensuring your system remains reliable. For any major residential electric upgrades, an expert opinion is a smart investment in your home’s safety.

When Connecting Generators or High-Voltage Systems

Connecting a standby generator is definitely not a DIY project. These systems are powerful and must be integrated into your home’s main electrical panel using a transfer switch. This is crucial to prevent dangerous backfeeding, which can injure utility workers and damage your equipment. A professional ensures your residential standby generator installation is done correctly and safely, following all electrical codes. The complexity of high-voltage systems requires the skill of a certified technician to guarantee it works flawlessly when you need it most.

To Guarantee Safety and Code Compliance

Even if your wiring extension works, is it truly safe and up to code? Professional electricians are experts in the National Electrical Code (NEC), which sets the standard for safe installation. They ensure every connection is secure, every junction box is accessible, and every wire is protected correctly. This isn’t just about following rules; it’s about preventing fires and ensuring your home passes inspection. If you feel unsure, it’s best to call an expert for electrician repairs or an inspection. A professional’s work gives you confidence that the job is done right.

The Final Step: Testing Your Work

You’ve done the hard part—the wires are extended, the connections are made, and everything is tucked into the junction box. But your work isn’t finished just yet. The final, and arguably most important, step is to test everything to make sure it’s not only functional but completely safe. This isn’t a step you can afford to skip. Properly testing your work confirms that your connections are solid, the wiring is correct, and you haven’t created any hidden electrical hazards. Taking a few extra minutes now provides peace of mind and ensures the safety of your home and family.

How to Safely Test the Circuit

With all your tools put away and the junction box cover securely in place, head back to your electrical panel. Find the breaker you switched off and flip it back to the “ON” position to restore power to the circuit.

Now, it’s time to test. The simplest tool for checking a new outlet is a plug-in outlet tester. These inexpensive gadgets have a series of lights that instantly tell you if the outlet is powered and wired correctly—confirming the hot, neutral, and ground wires are in their proper places. For more advanced testing, you can use a multimeter to check for the correct voltage. A properly functioning standard outlet in the US should read around 120 volts.

Final Safety Checks and Simple Troubleshooting

If your test shows everything is working correctly, give the area one last visual check. Make sure the cover plate is flush and secure and that there are no exposed wires.

What if the test fails? The very first thing you should do is go straight back to the breaker and shut the power off again. Never attempt to troubleshoot a live circuit. Once the power is off, you can safely open the junction box and re-examine your connections. Often, the issue is a loose wire nut or a wire that has slipped out of its terminal. Double-check that all your connections are secure and wired correctly. If you’ve reviewed your work and still can’t solve the problem, it’s time to call a professional. When it comes to your home’s safety, it’s always better to rely on expert electrician repairs than to take a chance.

Related Articles

- How to Run Electrical Wire in an Attic Safely

- The Ultimate Guide to Running Electrical Wire Through Walls

Frequently Asked Questions

Can I just use electrical tape to connect two wires together? No, you should never rely on electrical tape alone to splice wires. A proper connection requires a mechanical connector, like a wire nut, to securely join the wires. The tape is only for extra insulation, not for holding the wires together. All splices must be contained within a protective junction box to prevent fire hazards.

I turned off the breaker, but how can I be 100% sure the power is off? The best way to be certain is to use a non-contact voltage tester. After you flip the breaker, bring the tip of the tester near the wires you plan to work on. If it lights up or beeps, there is still electricity present, and you should not proceed. This is a critical safety step that professionals never skip.

Why can’t I just cover the junction box with drywall to hide it? Electrical code requires all junction boxes to remain accessible. This means you can’t bury them behind drywall, plaster, or insulation. If there’s ever an issue with the connection, you or an electrician need to be able to open the box to inspect and repair the wiring without tearing down a wall. Hiding a junction box is a serious safety violation.

Does the new wire I use have to be the exact same as the old one? Yes, it’s crucial that the new wire has the same gauge (thickness) as the existing wire. Using a wire that is too thin for the circuit’s electrical load can cause it to overheat, which is a major fire risk. You can find the gauge number printed on the outer sheathing of the wire.

When does a simple wire extension project become a job for a professional? You should call a professional if you feel uncertain at any point. Definite signs include discovering old or damaged wiring, needing to add a completely new circuit to your panel, or if the project involves a major appliance or a system like a standby generator. An expert can handle unexpected issues safely and ensure all work is up to code.