Our homes and businesses are more power-hungry than ever. Between electric vehicle chargers, high-end appliances, and workshops filled with heavy-duty tools, a standard 200-amp service can quickly reach its limit. If you find yourself constantly tripping breakers or worrying about overloading your system, it might be time for a serious upgrade. This is where a parallel feed electrical panel comes in. Instead of trying to force a massive amount of power through a single point, this system intelligently divides the electrical load across multiple panels. It’s a robust solution designed for high-demand environments, ensuring you have a stable and reliable power supply without compromising safety or performance.

Key Takeaways

- Choose a Parallel Feed System for High Power Needs: This setup is the go-to solution when a standard 200-amp panel can’t keep up. It’s designed to safely manage the significant electrical loads of large homes, properties with multiple buildings, or anyone needing a 400-amp service.

- Weigh the Benefits Against the Complexity: You gain superior power handling and can sometimes save on heavy-gauge wire costs, but the trade-off is a more intricate installation, higher labor expenses, and difficulty with whole-home energy monitoring.

- Rely on a Professional for a Safe Installation: This is not a DIY job. Critical safety measures like balancing the electrical load, sizing wires correctly, and ensuring proper single-point grounding require the expertise of a licensed electrician to prevent serious hazards.

What Is a Parallel Feed Electrical Panel?

When you think of your home’s electrical panel, you probably picture a single metal box in your basement or garage with rows of circuit breakers. While that’s the most common setup, some properties have a different arrangement called a parallel feed electrical panel. This system is designed to handle higher power demands by essentially splitting the workload. Understanding your home’s electrical configuration is the first step in making smart decisions about upgrades, repairs, and managing your energy use.

Defining the Basics

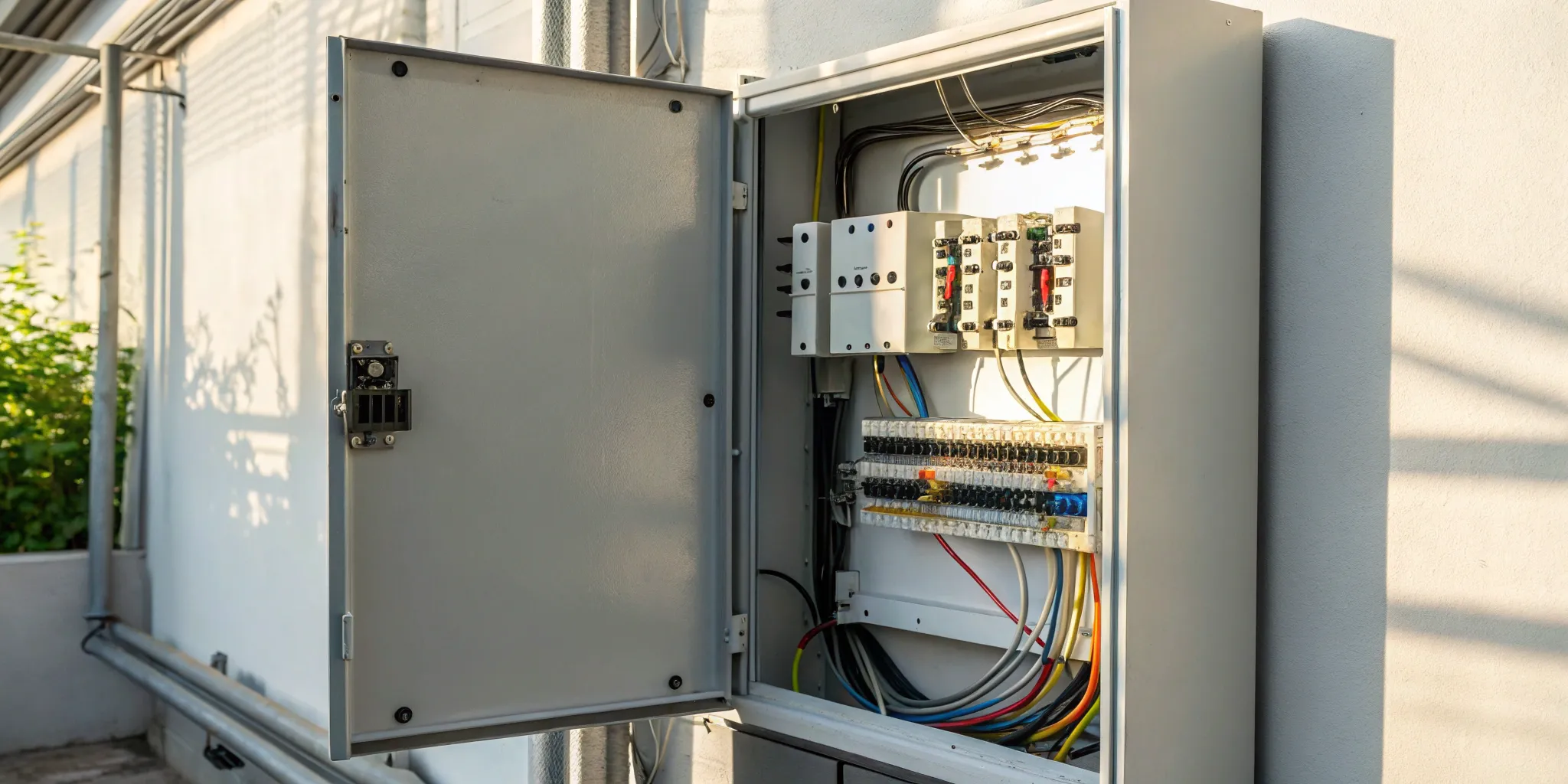

In a typical electrical system, power flows from the utility meter to one main breaker panel. From there, you might have smaller sub-panels for areas like a workshop or addition, but they all draw power from that single main source. A parallel feed system works differently. After the utility meter, the main power lines split and run to two or more separate, independent breaker boxes. Each of these acts as a main panel, or load center, for a different part of your property. It’s a distinct setup from a sub-panel, which is always downstream from a main breaker.

How a Parallel Feed System Works

The core idea behind a parallel feed system is to divide and conquer. By splitting the electrical service into two separate panels, the system can safely manage a much larger electrical load. The multiple sets of wires running from the service drop to the panels increase the total capacity, essentially doubling the amount of power your property can handle. This division of power is great for performance but can make it tricky to monitor your home’s total energy consumption with a single device. Because the power is split, any monitoring clamps would need to be installed correctly to capture data from both panels, a task best left to a professional handling your residential electric needs.

Where You’ll Find Them

Parallel feed panels are not standard in every house; they’re typically installed in situations with specific, high-power needs. You’re most likely to find this configuration on larger properties with multiple structures. For example, a home with a large, detached workshop, a guest house, or a garage full of heavy-duty tools might use a parallel feed system. This allows for a more balanced and efficient distribution of the electrical load across different buildings without overloading a single panel. If you suspect you have this setup and are experiencing issues, it’s important to call for electrician repairs from someone familiar with these more complex systems.

Parallel Feed vs. Traditional Panels: What’s the Difference?

When you think of your home’s electrical system, you probably picture a single main breaker box. That’s the traditional setup most of us are familiar with. But for homes and properties with higher power needs, a different configuration called a parallel feed is sometimes used. While both systems get the job done, they manage your home’s electricity in fundamentally different ways. Understanding these differences is key, especially if you’re planning major renovations or need to troubleshoot an issue. Let’s walk through what sets them apart.

Single vs. Multiple Panels

The most obvious difference is right in the name. A traditional electrical setup has one main panel. Power comes from the utility meter directly into this single box, which then distributes electricity to all the circuits in your home. If you have a sub-panel for a workshop or addition, it’s still fed from that one main panel.

A parallel feed system is different. After the utility meter, the main power lines split to feed two or more separate service panels. Each of these panels acts as a main panel, and neither is subordinate to the other. This setup is a core part of your home’s infrastructure, so any work on it requires professional residential electrical services.

How They Manage Your Power Load

So, why split the power? It’s all about handling a large electrical load. In a traditional system, a home with very high power demands would need incredibly thick, heavy wires running from the meter to the panel. These can be difficult and expensive to install.

A parallel feed system solves this by using multiple sets of smaller, more manageable wires. By running these wires “in parallel,” they can collectively carry the same amount of current as one giant wire. This approach is often more practical for properties with extensive electrical needs, as the smaller wires are easier to work with and have more surface area to dissipate heat, which helps them run efficiently and safely.

The Challenge of Monitoring Energy Use

One modern consideration is energy monitoring. Many homeowners now use smart devices to track their electricity consumption, which can help save money and spot problems. These monitors typically work by attaching sensors to the main power lines coming into your home.

With a traditional panel, this is straightforward because there’s only one place to measure. In a parallel feed system, however, the power is split. This makes it difficult for a standard energy monitor to capture a complete picture of your usage, as there isn’t a single point to clamp onto. While some workarounds exist, accurately tracking your total power consumption and identifying individual appliance usage can be more complex with this type of setup.

The Pros: Why Choose a Parallel Feed Panel?

When your property has serious power demands, a standard electrical panel might not be enough. A parallel feed system offers a smart solution by splitting your electrical service between two or more panels. While it sounds more complex, this setup comes with some major advantages, especially for larger homes, commercial buildings, or properties with high-demand equipment. If you’re planning a major renovation or new construction, understanding these benefits can help you design an electrical system that’s not only powerful but also efficient and scalable for the future.

The main advantages of a parallel feed panel boil down to three key areas: superior power handling, potential cost savings on materials, and a more organized, flexible system. Let’s break down what each of these means for you.

Handle More Power and Distribute It Evenly

One of the biggest reasons to choose a parallel feed system is its ability to manage a massive electrical load safely and effectively. Instead of using one enormous, hard-to-handle wire to bring power from the meter, this setup uses two or more smaller wires in parallel. Think of it like using two regular-sized hoses to fill a pool instead of one giant, heavy firehose—it’s just easier to work with.

This approach does more than just simplify installation. The smaller wires have more surface area relative to their volume, which allows them to cool down more efficiently. This prevents overheating and ensures your system can handle high-demand appliances, EV chargers, or even a commercial generator installation without strain. By distributing the load evenly, you get a more stable and reliable power supply.

Save on Materials for High-Demand Properties

It might seem counterintuitive, but installing two panels and more wiring can sometimes be cheaper than sticking with a single, traditional setup. The reason comes down to the cost of materials. The extremely thick, high-gauge copper wire needed for a 400-amp service or higher can be incredibly expensive and sometimes difficult to find.

In many cases, the combined cost of two sets of smaller, more standard-sized wires is less than the cost of one single, massive cable rated for the same amperage. For anyone undertaking a large-scale project, these material savings can be significant. It’s a practical way to get the power capacity you need without overspending on specialty components, making it a financially savvy choice for your residential electrical upgrade.

Better Organization and More Flexibility

A parallel feed system gives you a much cleaner and more organized way to manage your property’s circuits. With the electrical load split between two or more panels, you can dedicate each panel to a specific zone or function. For example, one panel might service the main living areas of your home, while a second panel handles the workshop, pool equipment, or a separate apartment.

This separation makes it far easier to label everything clearly and locate specific breakers when you need to. For electricians, this logical layout simplifies troubleshooting and future electrician repairs. It also gives you more flexibility for future additions, as you have more physical space in the panels to add new circuits without creating a tangled, overcrowded mess.

The Cons: Potential Downsides to Consider

While a parallel feed panel offers some great benefits for properties with high power demands, it’s not a one-size-fits-all solution. These systems come with their own set of challenges that you’ll want to think about before deciding if it’s the right fit for your home or business. From a more complicated installation process to difficulties with energy monitoring, understanding the potential drawbacks is key to making an informed choice. It’s important to weigh these factors carefully and discuss them with a qualified electrician who can assess your specific needs and ensure the job is done right.

Complex Installation and Higher Labor Costs

Installing a parallel feed electrical panel is definitely more complex than a standard setup. Instead of one large set of wires running from the meter to the panel, the system uses multiple, smaller wires in parallel. While this can make the wires themselves easier to handle, it makes the overall installation more intricate. This complexity means the job requires a high level of skill and precision. Because of the extra time and expertise involved, you can generally expect higher labor costs for these installations. It’s a project that should only be handled by experienced professionals who understand the specific requirements of these systems, which is why finding trusted electrician repairs and installation services is so important.

Meeting Code and Permit Requirements

Parallel feed systems are subject to strict electrical codes to ensure they are safe and reliable. Following these regulations can be tricky. For example, if any work needs to be done inside the utility meter box, such as placing monitoring clamps, you’ll almost certainly need to get permission from your electric company first, which isn’t always easy to obtain. Local codes can also have specific rules about how these systems must be configured. A licensed electrician with experience in your area will be familiar with these requirements and can manage the permitting process, ensuring your installation is fully compliant and safe from the start.

Tougher to Monitor and Troubleshoot

If you like to keep a close eye on your energy consumption, a parallel feed system can present a challenge. Because the power is split across multiple sets of wires, it’s difficult for energy monitoring devices to get a complete and accurate reading from a single point. Even if a monitor can capture your total electricity usage, its ability to identify individual devices and their consumption might be limited. This can also make troubleshooting more difficult. When an issue arises, pinpointing the exact location of the problem can take more time and effort, reinforcing the need for ongoing professional residential electric service.

Clearing Up Common Misconceptions

There’s often some confusion surrounding parallel feed panels, even among professionals. For instance, an electrician might not consider a standard single-phase 240V system to be a true “parallel situation” in the way they typically think of it. One of the most critical and sometimes misunderstood aspects is grounding. For safety, your entire electrical system should only be connected to the earth at one single point, which should be at the main service disconnect. Improper grounding in a parallel setup can create serious safety hazards. This is why it’s absolutely essential to work with an electrician who has proven experience with these specific configurations.

Getting It Installed: What You Need to Know

Installing a parallel feed electrical panel is a significant upgrade that requires precision, expertise, and a deep understanding of electrical systems. This isn’t a weekend DIY project; it’s a job that demands a licensed professional to ensure everything is safe, efficient, and up to code. From pulling the right permits to coordinating with your utility company, every step is critical. A proper installation guarantees your system can handle your property’s power demands safely for years to come. Let’s walk through the key things you need to know.

Following Local Codes and Hiring a Pro

First things first: electrical work is governed by strict local and national codes for a reason—safety. Any parallel feed installation must comply with these regulations, which can vary across Southeastern Pennsylvania. That’s why hiring a qualified professional is essential. An experienced electrician will handle all the necessary permits and inspections, ensuring your system is fully compliant. While using parallel runs can sometimes save money on materials, the complexity of the job means labor costs are a major factor. A professional can give you an accurate picture of the total investment and make sure the job is done right the first time, preventing costly and dangerous mistakes.

Placing the Main Disconnect and Panels

The layout of your parallel feed system is crucial for its function and safety. A common and effective setup involves installing a 400-amp main disconnect switch directly below the meter. From this central point, your electrician can then run separate feeds to each of your parallel panels. This approach creates a clean, organized system that makes it easy to manage power distribution across your property. It also provides a single, accessible shut-off point for the entire system, which is a key safety feature. Proper placement ensures that your electrical service is both logical and secure, forming a solid foundation for your property’s power needs.

Sizing Wires and Grounding Correctly

In any electrical system, using the correct wire size is fundamental, but it’s even more critical in a parallel setup. The wires must be identical in length, material, and size to ensure the electrical load is split evenly between them. Just as important is the grounding system. Each safety ground wire in a parallel setup must be correctly sized for the circuit’s overcurrent protection device, like a circuit breaker. This ensures that if a fault occurs, the safety measures will work instantly to protect your property and everyone in it. These precise calculations are a core part of a professional electrician’s repair and installation services.

Working with Your Utility Company

A parallel feed installation is a major upgrade that directly involves your connection to the power grid, so you can’t do it without the utility company’s involvement. Often, the work requires access to the utility meter box, and you’ll need permission from your electric company before making any modifications. Getting this approval can sometimes be a slow process, which is why it helps to have an experienced contractor managing the project. A professional team like M.T. Ruhl knows how to coordinate with local utilities, handling the communication and paperwork to keep your project moving forward smoothly and without unnecessary delays.

Staying Safe with a Parallel Feed System

A parallel feed system is a powerful solution for managing high electrical demands, but its complexity means that safety is the absolute top priority. Proper installation requires a deep understanding of electrical theory, load calculations, and local codes to ensure everything works correctly. When you’re dealing with this much power, even a small mistake can lead to big problems, from equipment damage to serious safety hazards.

That’s why working with a licensed professional is non-negotiable. An experienced electrician ensures every component is correctly sized, connected, and grounded according to strict safety standards. They know how to balance the electrical load perfectly between the panels and prevent dangerous situations like ground loops or overloaded circuits. At M.T. Ruhl, our team of experts handles these complex residential electrical services with the precision and care they demand, giving you peace of mind that your home or business is powered safely and reliably.

The Importance of Single-Point Grounding

Let’s talk about one of the most critical safety features of any electrical system: grounding. Think of the ground wire as an emergency exit for electricity. If there’s a fault, it provides a safe path for the current to travel to the earth, preventing electric shock and potential fires. With a parallel feed system, the rule is simple but strict: there should only be one place where the entire system is connected to the ground. This single-point grounding is almost always done at the main service panel and ensures that electricity has one clear, predictable path to safety, eliminating any confusion or potential for current to travel where it shouldn’t.

How to Balance Loads and Protect Circuits

The whole point of a parallel feed system is to handle more power by splitting it across multiple wires and panels. If you double the number of wires, you can effectively double the amount of electricity they can carry. However, this only works if the electrical load is balanced evenly. An electrician will carefully calculate your property’s power needs to ensure that no single wire or panel is carrying more than its share of the weight. Each parallel circuit is also protected by its own breaker, which acts as a safety switch to shut off power if a circuit becomes overloaded, protecting your property and your valuable equipment.

Preventing Dangerous Ground Loops

A “ground loop” sounds technical, but it’s a simple and dangerous concept. It happens when an electrical system is grounded in more than one spot, creating an extra, unintended path for electricity to flow. For example, someone might mistakenly add a second ground rod at a sub-panel in a detached garage. If the main ground wire were ever to break, this second path could become energized, turning your property’s grounding system into a serious hazard. A professional electrician understands how to design a system that completely avoids these dangerous loops, ensuring your grounding system works only as intended: for safety.

Common Safety Mistakes to Avoid

When it comes to parallel feed systems, precision is key, and there’s no room for error. One of the most common mistakes is using incorrectly sized wires. Specifically, the safety ground wire for each parallel run must be properly sized for the circuit breaker protecting it. If it’s too small, it can’t handle a fault current and may fail when you need it most. Other frequent errors include loose connections that can overheat and ignoring local electrical codes. These are just a few reasons why professional electrician repairs and installations are so important—we know what to look for and how to build a system that is safe, efficient, and up to code.

Is a Parallel Feed Panel Right for You?

Deciding on the right electrical setup for your property can feel overwhelming, but it really comes down to your specific needs. A parallel feed system isn’t a standard solution for every home or business; it’s a specialized setup designed for properties with significant power demands. If you’re running a large home, a commercial facility, or planning a major renovation, this type of panel might be exactly what you need to safely and efficiently manage your electricity. Let’s walk through a few scenarios where a parallel feed panel makes the most sense.

When Your Power Needs Are High

If your home or business requires a lot of electricity—more than a standard 200-amp service can provide—a parallel feed is a strong contender. When electrical demands are high, the main wires needed to carry that load become incredibly thick and difficult to work with. Instead of wrestling with one massive cable, a parallel feed system uses multiple smaller, more manageable wires. These smaller wires run alongside each other to carry the total current. This approach isn’t just for convenience; it’s also a matter of safety and efficiency. Multiple wires have more surface area, allowing them to cool down more effectively and handle the high amperage without overheating. This is a common solution for properties that need a 400-amp service or higher.

For Large Properties or Multiple Buildings

A parallel feed system is particularly useful for large properties with more than one building, like a home with a detached workshop, a large barn, or a guest house. In this setup, the main power from the utility company splits into two or more separate breaker boxes right after the meter. Each panel then serves a different part of your property. This is different from a sub-panel, which gets its power from your main breaker box. By splitting the feed at the source, you can deliver substantial, dedicated power to each building without overloading a single main panel. This ensures that your workshop has all the power it needs for heavy machinery without causing the lights to flicker in the main house.

During Major Upgrades and Renovations

Planning a big renovation or adding a large extension to your home? This is the perfect time to evaluate your electrical system. If your project involves adding significant electrical loads—like a new kitchen with high-end appliances, a hot tub, an EV charger, or a home workshop—you might outgrow your current panel. Integrating a parallel feed system during the renovation process can be a smart, forward-thinking move. It allows you to handle your immediate power needs and provides the flexibility to add more circuits in the future. It also sets you up perfectly for other major upgrades, like adding a residential standby generator to protect your entire property.

How to Maintain Your Parallel Feed Panel

A parallel feed electrical panel is a robust system, but it’s not something you can just set and forget. Like any critical part of your home or business, it needs regular attention to operate safely and efficiently. Proper maintenance helps you catch small issues before they become big, expensive problems, ensuring your system can handle your power demands for years to come. It’s all about being proactive rather than reactive, which keeps your property safe and your power supply reliable.

Why Regular Professional Inspections Matter

Because parallel feed systems are more complex than traditional panels, routine professional inspections are essential. An experienced electrician can verify that your setup remains compliant with electrical codes and, more importantly, is safe. During an inspection, a technician will check for things you can’t see, like loose connections or improper grounding. For these systems, it’s critical that all ground wires are securely connected to a single point to prevent dangerous electrical faults. Think of it as a regular health check-up for your electrical system, providing peace of mind and catching potential hazards early. If it’s been a while, scheduling an electrician for repairs and an inspection is a smart move.

Warning Signs to Watch For

You know your property best, so you’re the first line of defense in spotting trouble. Keep an eye out for a few key warning signs that your parallel feed panel needs attention. If you notice unusual heat coming from the panel, see your lights flicker frequently, or have breakers that trip repeatedly, don’t ignore it. These symptoms can indicate that the panel is overloaded or that there are loose connections inside. An improperly balanced load between the parallel conductors can also cause performance issues. If you notice any of these signs, it’s time to call a professional to diagnose the problem.

Ensuring Long-Term Performance

To keep your parallel feed panel running smoothly for the long haul, it’s important to think beyond immediate repairs. As your power needs change—maybe you’ve added an electric vehicle charger or new equipment—your system needs to keep up. A professional can perform load calculations to ensure your wire sizes are still adequate for the demand. They can also check that the conductors inside the panel are properly grouped and secured, which prevents wear and tear over time. This kind of preventative maintenance is key to the longevity and reliability of your residential electrical system.

Related Articles

- How Much to Replace an Electrical Panel in 2025?

- Price for Electrical Panel Upgrade: A 2025 Cost Guide

Frequently Asked Questions

How is a parallel feed panel different from a sub-panel? Think of it in terms of hierarchy. A sub-panel is always secondary; it gets its power from a breaker in your main electrical panel. A parallel feed system is different because it has two or more panels that are equals. Power comes from the utility meter and splits to feed each panel directly, meaning both act as main panels for different parts of your property.

Why would I choose a parallel feed system over a single large panel? It really comes down to managing very high power demands, like a 400-amp service. Instead of using one incredibly thick and expensive cable to power a single large panel, a parallel system uses multiple sets of smaller, more manageable wires. This approach can be more practical to install and often helps the system run more efficiently by distributing heat better.

Can I add a whole-home generator to a parallel feed system? Yes, you absolutely can, but the installation requires specific expertise. To power your entire property during an outage, a professional will need to install a transfer switch that is correctly configured to manage both of your main panels. This ensures that power is safely and evenly distributed from the generator to all the circuits you need.

What are the most common signs that my parallel feed panel needs professional attention? You should call an electrician if you notice any of the classic warning signs, like frequently tripping breakers, flickering lights, or warmth coming from the panel boxes. With a parallel system, these symptoms could point to an unbalanced load between the panels, which is a problem that needs to be addressed to prevent damage and ensure safety.

Are parallel feed panels more expensive to install? The final cost can be a bit of a trade-off. While you might save some money on materials by using smaller wires instead of one massive cable, the installation itself is more complex and time-consuming. This intricacy typically leads to higher labor costs, so you should expect the overall project to be an investment in getting a high-amperage service installed correctly.