Here in Southeastern Pennsylvania, our weather puts every part of our homes to the test, and the electrical service entrance is on the front lines. From humid summer air that promotes corrosion to winter ice storms that can strain connections, your system needs to be tough. This is why choosing the right electrical service entrance materials is about more than just meeting code; it’s about building a defense against our local climate. Materials must be weatherproof, UV-resistant, and capable of handling drastic temperature swings without failing. Selecting durable, high-quality components ensures your power supply remains stable and secure, preventing weather-related failures and costly repairs down the road. It’s an investment in reliability, no matter what the forecast holds.

Key Takeaways

- Your service entrance is your home’s power gateway: It’s the critical system that connects your house to the grid, and its proper installation is the first line of defense against electrical hazards.

- The right materials are non-negotiable: Components must be correctly sized for your electrical load and durable enough to withstand Pennsylvania’s weather to ensure a safe, reliable system for years to come.

- Professional installation is the only safe choice: A licensed electrician is essential for navigating complex safety codes, ensuring proper grounding, and preventing common but costly mistakes that can lead to fire or failed inspections.

What Is an Electrical Service Entrance?

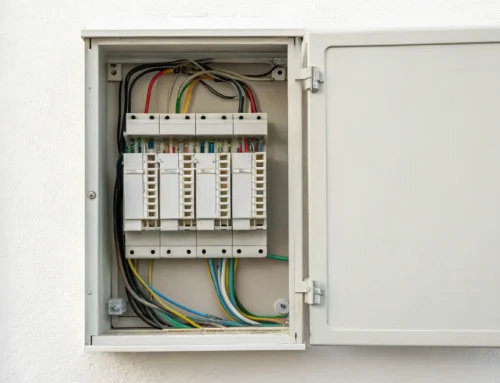

Think of your home’s electrical service entrance as the main gateway for all the power you use. It’s the critical connection point where electricity from the utility company’s grid flows into your house, powering everything from your lights and appliances to your HVAC system. This system is more than just a few wires; it’s a carefully designed setup that includes the overhead or underground lines coming to your home, the electric meter that tracks your usage, and the main service panel—often called a breaker box—that distributes power safely to different circuits.

Getting this entrance right is fundamental to having a safe and reliable power supply. It’s the first line of defense against electrical hazards and the foundation of your entire home’s electrical system. Whether you’re building a new home, upgrading an older system, or just want to understand how your house works, knowing about the service entrance is key. A properly installed and maintained service entrance ensures that your home receives a steady, safe flow of electricity for years to come. If you ever have concerns about your home’s electrical service, it’s always best to consult a professional.

How It Powers Your Home

The process starts with the service entrance cables, which are heavy-duty wires that tap into the utility’s power lines. These cables run to your electric meter, a device your power company uses to measure how much electricity you consume. From the meter, the power flows into your main service panel. This panel is the heart of your home’s electrical distribution, containing circuit breakers that act as safety switches. Each breaker is tied to a specific circuit in your home, like the kitchen outlets or the bedroom lights. When you flip a switch, power is drawn from the panel, through the circuit, and to your device. This setup ensures power is distributed efficiently and safely throughout your home.

Staying Safe and Up to Code

Because the service entrance handles all the electricity entering your home, safety is the top priority. All components and installation methods must follow the strict guidelines of the National Electric Code (NEC). These rules cover everything from the type and size of wires used to the proper placement of the main shut-off switch. Components are also tested to meet safety standards, ensuring they are reliable. Following these codes prevents dangerous situations like electrical overloads and fires. This is why any work on your service entrance should be handled by a licensed electrician. They have the expertise to ensure every connection is secure, weatherproof, and completely up to code, keeping your home and family safe.

The Essential Parts of a Service Entrance

Think of your electrical service entrance as the main gateway for all the power your home uses. It’s not just one single part, but a system of components working together to safely bring electricity from the utility lines into your electrical panel. When we perform a residential electrical installation, our team focuses on getting every piece of this system right, because there’s no room for error when it comes to your home’s power supply. Understanding these essential parts can help you appreciate what goes into a safe and reliable electrical setup. From the heavy-duty cables that carry the current to the smallest fittings that keep water out, each component plays a critical role in protecting your home, your appliances, and your family. This system is the first line of defense against power surges, short circuits, and weather-related damage. Getting it right means having peace of mind that your lights will stay on and your home will remain safe. Let’s walk through the key players that make up your service entrance.

Service Entrance Cables (SE Cables)

The service entrance cables are the thick, bundled wires that act as the main power line from the utility’s connection point to your meter and then to your main electrical panel. These are the workhorses of your electrical system. You’ll typically encounter two main types of service entrance cables: SER and SEU. SER cable is the more modern option, containing four wires that include a separate ground wire for added safety. SEU cable, on the other hand, has three wires and is often found in older homes. Choosing the right cable depends on your home’s specific needs and local code requirements, which is a key part of any professional assessment.

Conduit and Protective Housing

To protect the service entrance cables from the elements and physical damage, they are often housed inside a pipe called a conduit. This is essentially a protective sleeve, usually made of metal or plastic, that runs from the weatherhead (the cap where the wires enter from the utility pole) down to your electric meter base. This protective housing is crucial for shielding the wires from everything from falling tree limbs to accidental bumps from a lawnmower. It ensures the integrity of your electrical connection remains intact and safe from external threats, keeping your power supply secure and uninterrupted.

Connectors and Fittings

Connectors and fittings might seem like minor details, but they are vital for a secure and weatherproof service entrance. These are the components that attach the conduit to your meter base and electrical panel. High-quality connectors and fittings, like locknuts and bushings, create a tight seal that prevents water from seeping into your electrical panel—a major cause of corrosion and electrical hazards. A professional electrician ensures every connection is perfectly sealed and secured, because even a small leak can lead to big problems. It’s this attention to detail that defines a safe and durable installation.

Grounding Equipment

Grounding is one of the most important safety features of your entire electrical system. The grounding equipment, which includes a grounding electrode conductor (a wire) and a grounding electrode (usually a long copper rod driven into the earth), provides a safe path for excess electricity to dissipate into the ground. This prevents electrical surges from damaging your appliances and, more importantly, protects you from dangerous electrical shocks. The National Electrical Code has very specific requirements for grounding equipment, including the minimum size for grounding wires. Proper grounding is non-negotiable for a safe home.

Meeting Safety Standards and Codes

When it comes to your home’s electrical system, safety isn’t just a suggestion—it’s a requirement backed by strict rules and regulations. These codes aren’t about creating red tape; they exist to protect your property, your family, and your business from the serious risks of fire and electrical shock. Think of them as the absolute minimum standard for a safe installation. A qualified electrician doesn’t just meet these codes; they understand the principles behind them to ensure your service entrance is reliable and secure for the long haul.

Navigating these standards involves a multi-layered system of national guidelines, product certifications, and specific local rules. The National Electric Code (NEC) provides the foundation, Underwriters Laboratories (UL) certifies that the materials themselves are safe, and your local municipality adds its own requirements. This is precisely why professional electrician repairs and installations are so critical. An experienced electrician is fluent in this language of safety, ensuring every component and connection is fully compliant and built to last. It’s about giving you peace of mind that the job was done right.

National Electric Code (NEC) Rules

The National Electric Code, or NEC, is the benchmark for safe electrical installation across the United States. It’s a comprehensive rulebook that electricians use to design and install electrical systems that are free from hazards. For your service entrance, a specific section called Article 230 is especially important. It outlines the essential requirements for bringing power from the utility lines to your home or business.

This includes everything from the correct wire sizes and types to the proper placement of your main power shut-off switch and the necessary protections against overloads. Following these NEC guidelines ensures your service entrance can handle your electrical load safely and reliably, preventing dangerous situations before they can happen.

UL Standards and Certifications

While the NEC sets the rules for installation, how do you know the materials themselves are safe? That’s where UL certification comes in. UL, which stands for Underwriters Laboratories, is a globally recognized safety organization that tests and certifies products. When you see the UL mark on a service entrance cable, breaker, or any other electrical component, it means that the product has passed rigorous testing for safety and performance.

For example, service entrance cables must meet UL 854 standards to prove they are safe for use. Using UL-certified materials is a non-negotiable part of a professional installation, giving you confidence that every part of your system is built to perform safely under real-world conditions.

Local Pennsylvania Codes

The NEC provides a national standard, but your local town or county often has its own set of rules that may be even more specific or stringent. Here in Southeastern Pennsylvania, each municipality can have unique requirements for electrical installations. These local codes might dictate specific materials, installation methods, or additional safety measures that go beyond the national guidelines.

This is where hiring a local, licensed electrician is invaluable. We are familiar with the specific codes and permit requirements in all the service areas we cover, from Chester County to Bucks County. This local expertise ensures your project is not only safe but also fully compliant, avoiding failed inspections, costly rework, and potential safety hazards down the line.

How to Choose the Right Service Entrance Materials

Choosing the right materials for your electrical service entrance is one of those behind-the-scenes decisions that has a huge impact on your home or business’s safety and reliability. It’s about more than just connecting to the grid; it’s about building a durable, code-compliant system that can handle your power needs for years to come. Think of it as the main artery for your property’s power—if it’s not strong and well-protected, the entire system is at risk. The wrong components can lead to frequent problems, safety hazards, and costly electrician repairs down the road.

Making the right choice means looking at a few key factors unique to your property and location. While the technical details can seem complex, understanding the basics helps you have a more informed conversation with your electrician and appreciate why certain materials are recommended over others. We’ll walk through how to assess your electrical load, account for our local Pennsylvania climate, and understand the different requirements for residential and commercial properties. Getting these details right from the start ensures your electrical system is built on a solid, safe foundation that you can depend on.

Assess Your Electrical Load

First things first, you need to know how much power you’re actually using. This is your electrical load, which is a calculation of all the appliances, lighting, and equipment your property will run at the same time. For example, a standard 200 Amp service requires at least 3/0 AWG copper wire or 4/0 AWG aluminum wire to operate safely. Using a smaller wire would push it to its maximum capacity, creating a serious fire risk. An experienced electrician can perform a load calculation to determine your exact needs, ensuring your system is adequate for today and can also handle future additions. This is a critical first step in any residential electric project.

Consider Your Local Climate

Here in Southeastern Pennsylvania, our electrical systems have to endure everything from humid summer days to icy winter storms. These weather extremes can take a toll on exterior components, causing corrosion, cracking, and water intrusion if they aren’t up to the task. That’s why it’s so important to select materials built to last. For instance, aboveground service entrance cables like SER and SEU come with a durable covering that resists moisture and fire. Choosing weatherproof and UV-resistant conduits, fittings, and enclosures ensures your service entrance remains sealed and secure, protecting the critical connections from the elements year-round and preventing weather-related outages.

Residential vs. Commercial Needs

The electrical demands of a single-family home are very different from those of a commercial building, and the service entrance materials must reflect that. A typical home has one service entrance where power enters, connecting to an electric meter and a service panel with circuit breakers. Commercial properties, however, are often more complex. A large building might require multiple service entrances to supply power to different businesses or to accommodate equipment with varying voltage needs. This requires a more robust and specialized design. Properly planning a commercial generator installation or electrical service means selecting industrial-grade components that can handle higher loads and more complex configurations safely.

Which Service Entrance Cable Is Right for You?

Choosing the right service entrance cable is one of the most important decisions for your home’s electrical system. This heavy-duty cable is the main artery that carries all the power from the utility lines into your house, so getting it right is non-negotiable for safety and performance. While a licensed electrician will always make the final call based on your specific needs and local codes, understanding the options can help you have a more informed conversation about your project.

The choice isn’t one-size-fits-all. It depends on your home’s power requirements, whether your service line runs overhead or underground, and the specific regulations in your area. The three main factors to consider are the cable type (SER vs. SEU), its installation location (above-ground vs. underground), and the conductor material (aluminum vs. copper). Each of these elements plays a crucial role in ensuring your electrical service is reliable and, most importantly, safe. Making the wrong choice can lead to failed inspections, safety hazards, or an electrical system that can’t handle your family’s needs. That’s why working with a professional for any residential electrical work is so critical.

SER vs. SEU Cables

At first glance, SER and SEU cables look similar, but they have a key difference in their wiring that dictates where they can be used. SEU (Service Entrance, Unarmored) cable has a neutral wire but lacks a separate ground wire. Because of this, it’s typically only permitted for use as the main line running from the weatherhead to your meter base and service panel.

SER (Service Entrance, Reinforced) cable, on the other hand, contains both a neutral wire and a separate ground wire. This extra wire makes it more versatile and safer for interior wiring after the main service panel. You’ll often see SER cable used to run power to major appliances like dryers and ranges or to feed a sub-panel in a garage or workshop.

Above-Ground vs. Underground Cables

How power gets from the utility pole to your house also determines the type of cable you need. For overhead service drops, standard SE cables are used. However, if your power lines are buried, you’ll need a special cable rated for direct burial. These are known as USE (Underground Service Entrance) cables.

USE cables are built to withstand the harsh underground environment. They feature a tough, moisture-resistant jacket that protects the conductors from soil, rocks, and water. This durability is essential for preventing damage and ensuring a long, reliable service life. Choosing an underground service can offer a cleaner look and better protection from storm damage, a common concern for homeowners who invest in Generac generators.

Aluminum vs. Copper Conductors

The wires inside your service entrance cable will be made of either aluminum or copper. Most modern service entrance cables use a strong, lightweight aluminum alloy. Aluminum is significantly less expensive than copper, making it a popular choice for the heavy-gauge wires needed for a service entrance.

However, copper is a better electrical conductor. This means you can use a smaller copper wire to carry the same amount of current as a larger aluminum one. For example, a standard 200-amp service requires a 4/0 AWG aluminum wire but only a 3/0 AWG copper wire. A professional electrician will perform a load calculation to determine the right amperage for your home and select the appropriate wire size and material to meet code and safely power your home.

Choosing Materials That Withstand the Elements

Southeastern Pennsylvania’s weather is anything but predictable. We get hot, humid summers, freezing winters, and plenty of rain and snow in between. Your electrical service entrance is exposed to all of it, day in and day out. That’s why selecting materials built to last isn’t just a good idea—it’s essential for the safety and reliability of your home’s power supply. The right components will resist corrosion, handle temperature swings without failing, and reduce fire risks, saving you from future headaches and costly fixes. When materials degrade, it can lead to flickering lights, tripped breakers, or even complete power loss. Making smart choices from the start ensures your system remains secure and functional for years, no matter what the weather throws at it. If you’re ever concerned that weather has taken a toll on your existing setup, professional electrician repairs can identify and resolve any vulnerabilities.

Moisture and Humidity

Humidity is a constant battle in our region, and moisture is electricity’s worst enemy. When water seeps into your service entrance, it can corrode metal components, compromise connections, and lead to dangerous short circuits. To prevent this, we use specific materials designed for wet and damp conditions. For example, aboveground service entrance cables like SER and SEU come with a special covering that is both moisture- and flame-resistant. This protective jacket acts as a barrier, ensuring the conductors inside stay dry and secure, even when pulled through walls or exposed to the elements.

Temperature Changes

From scorching July afternoons to frigid January nights, the materials in your service entrance are constantly expanding and contracting. Over time, this thermal stress can cause connections to loosen and insulation to crack, creating serious safety hazards. That’s why it’s crucial to use components rated for wide temperature ranges. For instance, wires with XHHW-2 insulation are an excellent choice for areas with high humidity and significant temperature shifts, especially when run inside a conduit. These materials are engineered to remain flexible and durable, maintaining their integrity through every season.

Fire Resistance

Fire safety is the most important consideration for any electrical work. Your service entrance handles a massive amount of power, and using materials that aren’t fire-resistant is a risk you can’t afford to take. Professional-grade service entrance cables are designed with safety as the top priority. Most are made with a strong aluminum alloy (AA-8000 series) and feature a flame-retardant jacket. This ensures that even if the conductors overheat, the cable’s covering will resist catching fire, helping to contain the danger. Investing in proper residential electrical services guarantees that every component is chosen to protect your home and family.

Key Installation Techniques

Choosing high-quality materials for your service entrance is the first step, but it’s the installation that truly makes or breaks the system. The techniques a professional electrician uses are designed to ensure your home’s power supply is safe, reliable, and built to last for decades. These methods protect your system from everything from electrical surges to the harsh Pennsylvania weather. It’s the combination of the right parts and expert craftsmanship that provides real peace of mind. A properly installed service entrance is a silent guardian for your home, and these key techniques are what make it so effective.

Proper Grounding and Bonding

Think of grounding as the ultimate safety net for your home’s electrical system. It provides a direct, safe path for excess electrical current to travel into the earth, preventing it from causing electric shocks or starting a fire. Bonding works alongside grounding by connecting all the metal components of your electrical system—like conduits, enclosures, and pipes—to ensure they are at the same electrical potential. This eliminates dangerous voltage differences between objects. Proper grounding and bonding are non-negotiable for safety and are a foundational part of any professional electrical service. They protect not just your expensive electronics and appliances, but more importantly, your family.

Creating a Drip Loop

One of the simplest yet most critical installation techniques is the drip loop. Before the service entrance cable enters your home through the weatherhead, an electrician will form a U-shaped bend in the wire. This small detail serves a huge purpose: it uses gravity to its advantage. Any rainwater or melting ice running down the cable will travel to the bottom of the loop and drip safely to the ground instead of flowing into your electrical equipment. It’s a straightforward but brilliant way to prevent water from infiltrating your system, which could otherwise lead to short circuits, corrosion, and serious electrical repairs.

Securing Connections to Prevent Water Damage

Beyond the drip loop, every connection point in your service entrance must be perfectly sealed and secured. The mast, conduits, and cables need to be weather-tight to create an impenetrable barrier against the elements. In our region, where we see everything from heavy rain to freezing snow, this is especially important. An experienced electrician ensures that all components are firmly in place and not bent or pulled out of position, as any gap can become an entry point for moisture. A secure, well-sealed system prevents water ingress that can lead to electrical failures, hazards, and costly damage over time, ensuring your home stays powered and protected no matter the weather.

Common (and Costly) Service Entrance Mistakes

Your home’s electrical service entrance is not the place for a weekend DIY project. While it might seem straightforward, this critical connection point between the utility grid and your home has no room for error. Small mistakes here can lead to major safety hazards, failed inspections, and expensive repairs down the line. Getting it right the first time protects your home, your family, and your wallet.

When it comes to your service entrance, a few common installation errors pop up more than others. These aren’t just minor slip-ups; they can compromise the integrity of your entire electrical system. Understanding these pitfalls is the first step to ensuring your home’s power supply is safe, reliable, and up to code.

Using Undersized Components

Choosing the right size for your service entrance components is crucial. Using wires, conduits, or fittings that are too small for your home’s electrical load is like trying to send a river through a garden hose—it creates dangerous pressure. Undersized wires can overheat, melting their protective insulation and creating a serious fire risk. This mistake also guarantees a failed electrical inspection, which means you’ll have to pay to have the work redone. Professional electrician repairs often involve fixing improperly sized components to meet safety standards and ensure the system can handle your home’s power demands without issue.

Forgetting to Weatherproof

Your service entrance is constantly exposed to the elements, from driving rain to snow and ice. Proper weatherproofing is essential to prevent moisture from getting inside your electrical system. Common mistakes include installing the service cap incorrectly, forgetting to create a drip loop to guide water away, or failing to seal the conduit where it enters your home. When water seeps into your service panel, it can cause corrosion, short circuits, and even electrical fires. A properly installed residential electric system includes meticulous weatherproofing to protect these vulnerable connection points and keep your home’s power supply safe and dry, no matter the weather.

Making Poor Connections

Even with the right materials, a loose or improper connection can undermine the entire installation. Every wire connection must be tight and secure to ensure a consistent flow of electricity. A loose connection can cause arcing—a dangerous spark that can jump between wires—which can lead to power outages and fires. Simple oversights, like forgetting to apply an antioxidant compound to aluminum wires or failing to seal the conduit entrance with putty, can lead to corrosion and a faulty connection over time. This is why having a professional from M.T. Ruhl handle your installation is so important; we ensure every detail is perfect.

Why You Should Hire a Professional Electrician

While tackling a home improvement project yourself can be rewarding, electrical work isn’t the place to test your DIY skills. Your home’s service entrance is the connection point to the entire power grid, and a mistake here can have serious consequences. The main reason to call a professional is safety. Service entrance cables are live and aren’t protected by a circuit breaker until they reach the main panel, creating a significant risk of shock or fire if handled improperly. A trained professional has the experience and equipment to perform these electrical repairs safely.

Beyond the immediate dangers, there’s a complex web of regulations to follow. Professional electricians have a deep understanding of the National Electric Code (NEC) as well as specific state and local codes here in Pennsylvania. These rules are in place to protect you, your family, and your property. An expert ensures every component is correctly sized, installed, and grounded, guaranteeing your system is not only functional but also fully compliant. This protects you from potential fines and issues with home inspections down the road.

Hiring an experienced electrician is an investment in your home’s long-term health and your peace of mind. They can assess your specific power needs, recommend the right materials, and ensure the installation is done correctly the first time. This prevents common but costly mistakes like using undersized wires or making poor connections, which can lead to power failures and damage to your appliances. When it comes to the system that powers your entire life, it’s always best to trust the work to someone who does it every day.

Related Articles

- How to Run Electrical Wire in an Attic Safely

- Hiring an Electrical Repair Service? Read This First

- Best Location for an Electrical Panel: A Pro’s Guide

Frequently Asked Questions

How can I tell if my older home’s service entrance needs an upgrade? If your home still has a fuse box or a service rated for less than 100 amps, it’s a strong candidate for an upgrade. Other signs include flickering lights, frequently tripped breakers, or buzzing sounds from your electrical panel. As our power needs have grown with modern appliances and technology, many older service entrances can’t safely keep up. A professional assessment can determine if your current system is sufficient or if an upgrade is needed to safely power your home.

What are the signs of a problem with my electrical service entrance? You should keep an eye out for any visible wear and tear on the exterior components. Look for frayed or cracked insulation on the cables, rust on the meter box or conduit, or if the mast holding the wires appears bent or pulled away from the house. Inside, if you notice a burning smell near your panel or your lights dim whenever a large appliance like the air conditioner kicks on, it’s time to call an electrician for an inspection.

What’s the difference between an overhead and an underground service? An overhead service is the more traditional setup, where the service entrance cables run from a nearby utility pole to the mast on your roof. It’s generally less expensive to install and easier for utility workers to access for repairs. An underground service runs the cables in a conduit buried in a trench from a transformer to your meter. While it costs more upfront, it offers a cleaner look and better protection from storm damage and falling tree limbs.

Why can’t I just replace the parts of my service entrance myself? The primary reason is safety. The wires coming from the utility pole to your meter are always live, even when your main breaker is off. There is no DIY-safe way to shut them off, which creates an extreme risk of electrocution. This work also requires a deep understanding of national and local electrical codes, as well as permits and inspections. A small mistake can lead to a fire, failed inspection, or serious injury.

My breaker box is full. Does that mean I need a new service entrance? A full breaker panel is often a sign that your entire electrical service may be undersized for your needs. Simply adding a sub-panel isn’t always the answer if the main service entrance cables can’t handle the additional load. In many cases, upgrading to a larger panel with more circuits will also require upgrading the service entrance cables and meter base to a higher amperage, like 200 amps, to safely support your home’s power demands.